For most consumers, fragrance is emotional. For founders, it’s structural....

Read MoreTechnology & Electronics Manufacturing

Build reliable, scalable technology products with vetted electronics manufacturers, proven engineering practices, and sourcing expertise from prototype to production.

How Sourcify Supports Your Electronics Sourcing

We guide you through complex engineering, compliance, and manufacturing decisions so your product moves from prototype to production with confidence.

Vetted Electronics Manufacturers

We source factories with strong SMT lines, proven QA systems, and reliable component supply chains.

Compliance Guidance (FCC, CE, RoHS)

We support EMC, RF, and safety pre-testing, helping reduce certification failures.

Structured QA & Production Oversight

From AOI to functional testing to firmware flashing, we ensure consistent electronics quality.

Design for Manufacturing Support

We help you optimize PCBs, enclosures, and BOMs for cost, reliability, and certification readiness.

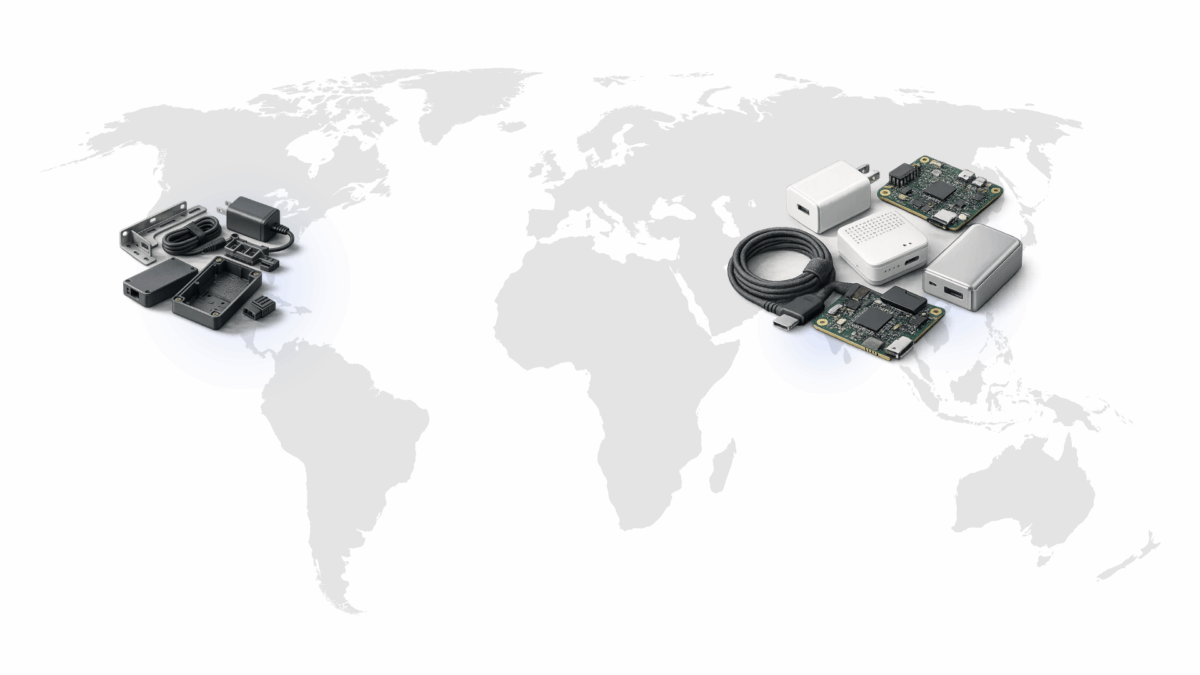

Multi-Country Manufacturing Options

Leverage China, Taiwan, Vietnam, and Mexico depending on cost, complexity, and logistics needs.

End-to-End Production Support

Quotes, samples, revisions, testing, and issue resolution handled by experts who understand electronics.

Best Countries for Manufacturing Technology & Electronics

Ideal For:

IoT devices, consumer electronics, PCBs, chargers, cables, accessories.

Cost Snapshot: Medium

Lead Times: 45–120 days

Ideal For:

PCBs, IoT modules, RF-critical devices.

Cost Snapshot: Medium–High

Lead Times: 45–90 days

Ideal For:

Cables, chargers, accessories, assembly-heavy devices.

Cost Snapshot: Low–Medium

Lead Times: 60–120 days

Ideal For:

Cables, chargers, accessory assembly, enclosures.

Cost Snapshot: Medium

Lead Times: 30–60 days

Ready to Build Your Tech Product with Confidence?

Get matched with a vetted electronics manufacturer and move from prototype to production with expert support.

Technology & Electronics Types We Support

From PCBs to smart devices to accessories, we connect you with factories experienced in precision electronics, high-quality enclosures, and scalable assembly.

PCBs & PCB Assemblies (PCBA)

Multilayer PCBs, SMT/THT assemblies, IoT boards, and firmware-flashed units built with AOI, X-ray, and functional testing.

IoT & Smart Devices (Non-Medical)

Bluetooth, Wi-Fi, and sensor-enabled devices produced with RF testing, antenna tuning, and consistent enclosure fitment.

Electronics Accessories

Cases, mounts, stands, docks, protective housings, and precision plastic or silicone accessories.

Chargers & Power Adapters (UL/ETL Capable)

USB-C chargers, multi-port adapters, and wall chargers manufactured with built-in safety protections and global compliance options.

Cables & Connectors

USB-C, USB-A, Lightning-style accessories, braided cables, charging cords, and custom connectors with strong strain relief.

Wearables & Small Devices (Non-Medical)

Compact devices with PCBA, sensors, LEDs, and molded enclosures assembled with ergonomic and durability considerations.

Plastic, Silicone & Metal Enclosures

Injection-molded housings, CNC aluminum parts, silicone overmolds, and EMI-safe shielding components.

Key Manufacturing Risks to Avoid

Electronics require precision, safety, and consistency. Here are the issues that most commonly lead to failures, compliance problems, or costly rework.

Poor Component Sourcing

Unverified suppliers or inconsistent IC batches lead to failures, yield issues, or counterfeit risks.

Weak SMT Processes

Cold solder joints, tombstoning, bridging, or missing components cause device instability.

RF Performance Issues

Misplaced antennas, poor grounding, or enclosure interference cause Bluetooth/Wi-Fi failures.

Thermal Management Failures

Overheating from poor thermal design or inadequate heat sinking reduces product lifespan.

Lack of Functional & Compliance Testing

No RF, EMC, or power safety testing = high certification failure rates.

Uncontrolled Revisions

BOM, firmware, and Gerber mismatches lead to production mistakes and inconsistent units.

When Brands Seek a New Manufacturer

These signals often indicate your current factory isn’t keeping up with the engineering rigor or quality needed for electronics production.

- High PCB defect rates (low yield)

- Inconsistent SMT quality or reflow issues

- Failed FCC/CE compliance tests

- Overheating or RF performance problems

- Poor enclosure fitment or tolerance issues

- Counterfeit or inconsistent electronic components

- Slow lead times during component shortages

- Weak QA reporting or documentation gaps

- Lack of AOI/X-ray or test jigs

- Firmware flashing inconsistencies

Frequently Asked Questions

Most devices require FCC (U.S.), CE (Europe), and RoHS compliance. IoT products require RF testing. Chargers typically need UL/ETL or equivalent. We help navigate these requirements.

Poor PCB assembly processes (cold solder joints, component misplacement) and incomplete testing plans are the most frequent causes.

China and Taiwan lead in PCB and IoT devices. Vietnam excels in cables and assembly. Mexico provides nearshore options for accessories and simple electronics.

Yes. We provide DFM guidance, component sourcing checks, and pre-certification testing recommendations.

PCBs/PCBA: 2–6 weeks

Enclosures: 4–8 weeks

Full device production: 8–16 weeks

Certification adds additional time.

Recent Electronics Blogs

How Fragrance Is Actually Made (And Why Packaging Is the Real Cost Driver)

Most founders assume fragrance costs live in the formula. They...

Read More10 Steps to Avoid Quality Risks and Bad Suppliers

Choosing the wrong manufacturer is one of the most expensive...

Read MoreWhat’s the Best Way to Vet a Manufacturer Overseas?

When it comes to overseas manufacturing and global sourcing, one...

Read MoreReady to Build Your Tech Product with Confidence?

Get matched with a vetted electronics manufacturer and move from prototype to production with expert support.