Getting impatient?

If you’ve waited longer than expected for a package or walked into a store with sparsely filled shelves, you’re one of the billions experiencing the global supply chain crisis.

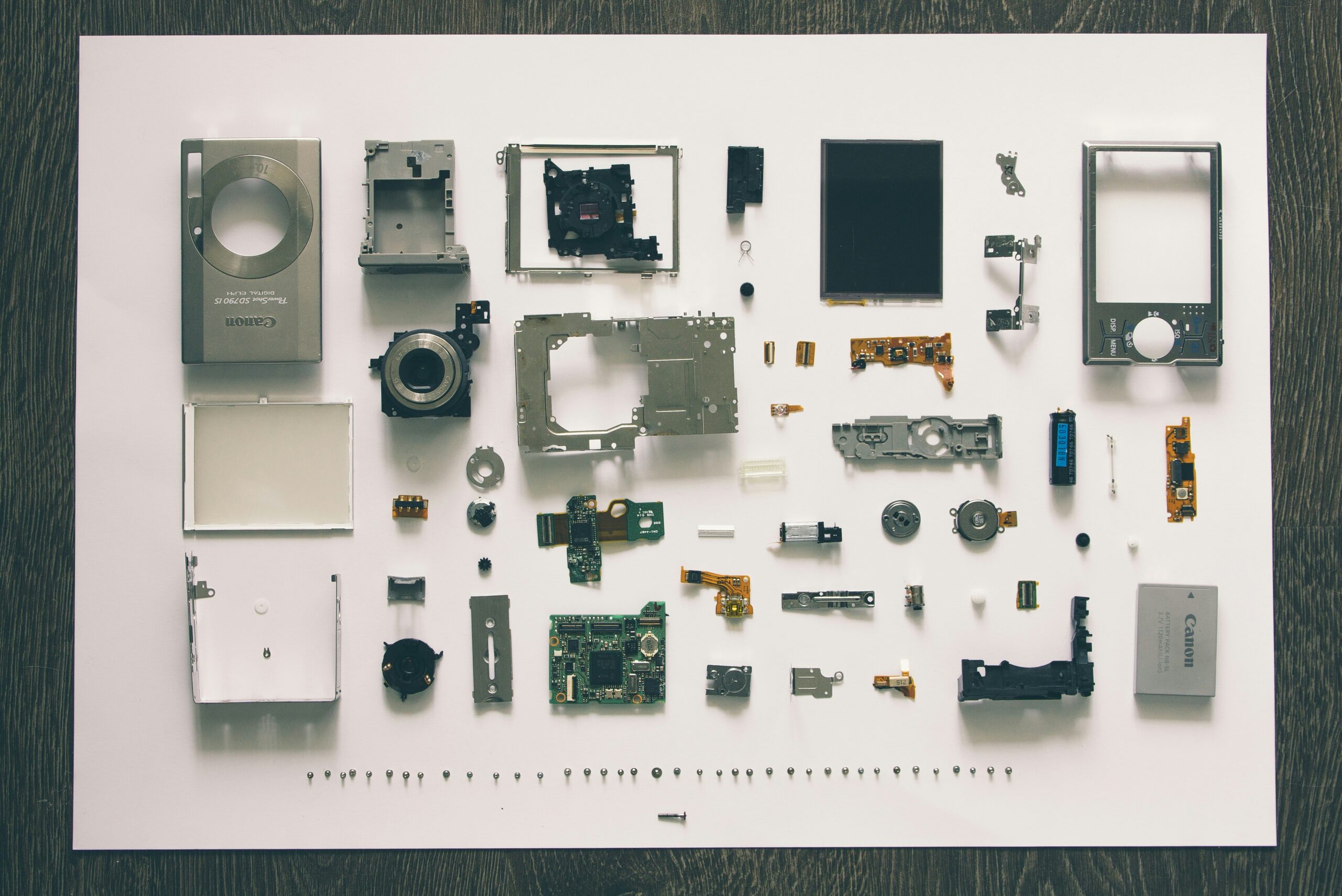

Running shoes, lumber, cars, medicine, toys, even garlic, these are just a few of the things you may have had trouble getting your hands on. A simpler way to characterize what products are affected by the crisis: all of them.

How Long Has This Been Going On?

Problems began in spring 2020. It’s hard to hear that time and not think of something else colossal taking place concurrently: the coronavirus pandemic.

If you pinned those events as connected, you would be all too correct.

What Does the Coronavirus Have to Do With the Crisis?

A lot. When the virus began its terrifying sweep across the world, a complicated and far-reaching cascade of events followed it. First, the direct effects of those who actually became sick. The virus hit hard in countries where a lot of the world’s manufacturing takes place — think China, South Korea, and Germany. Factories which usually pump out global wares had to reduce their output or even shut down as workers became sick or were quarantined.

Next, the effect of the shutdowns in cities across the world. To prevent the spread of the virus, many authorities enacted restrictions, keeping many people from work, stores, and restaurants. Individuals also personally chose to restrict their activities, holing up in their homes for safety. This led to an enormous economic slowdown.

The cascading events picked up speed as the economic slowdown led to lay-offs, which led to less spending power, which led shipping companies to believe — along with the above-mentioned fact that factories in Asia and Europe were slowing production — that the demand for the transport of goods would drop significantly. They reduced their shipping schedules as a result.

Unfortunately, this was a huge miscalculation.

In fact, upon being forced to spend more time at home, people began to order more goods. Many now worked, attended school, exercised, and cooked all from home.

Home offices were built, personal preschools were established, YouTube workouts increased, and kitchens were decked out. As a result, orders for office chairs, electronics, workout equipment, and kitchen tools leapt. This brings us back to the shipping problem.

With the pandemic there came a surge in demand for PPE. China, as the primary manufacturer of things like masks and surgical gowns, began shipping containers filled with much-needed equipment to all parts of the globe. The problem was, some of these places usually did little trade with China, and as a result shipping containers began piling up in corners of the world, unused, as China continually needed more.

What’s more, with the stimulus checks being sent to Americans, the trend of online shopping continued to increase. If manufacturers could attain the shipping containers they needed, get them loaded, and move them across the sea with the trim shipping schedules, there was another problem at the ports.

Overcrowding became a big issue a few months into the pandemic. It was reported that at times there were 100-vessel lines to get to the ports of some California cities. Each container that sits outside a port waiting to be unloaded further slows down the supply chain, as it can’t be used to ship something else. Supply is simply outstripped by demand.

Once finally in the ports, the problems continued. A shortage of truck drivers led to some containers being left at the ports, miles short of their final destinations.

Is It All Due to the Pandemic?

The pandemic certainly put things into action (though a better word choice might be “confusion”). But there were several factors stewing before we ever heard of Covid-19.

First, the concept of “just-in-time” manufacturing, introduced by the Ford company in the 1940s. Whereas manufacturing had previously been dictated by a production-push basis, it switched to a demand-pull basis in an effort to minimize overproduction and holding costs, among other factors. With this model of production, real orders determine what is manufactured.

This may be a smart, money-saving model when the supply chain is reliable, but it’s a catastrophe when the opposite is true. Companies using JIT manufacturing have very few components stockpiled and rely on imports, and quick ones at that. When imports were interrupted or delayed, the effect felt by JIT companies was immediate, and consumers did not get the products they needed.

Second, the shortage of truck drivers. Truck driving is a demanding job and the number of people who take it up is not large, especially as pay fails to keep up with inflation. The pandemic certainly did not help to increase this shortage, as businesses everywhere struggled to find workers.

Third, online shopping was increasing in popularity before the pandemic. Retailers and shipping companies were already having to adjust their schedules and practices, and then the workload blasted into the stratosphere as people ordered everything they might want or need from their laptops or phones.

How Long Will This Last?

Unfortunately, no one really knows. Shortages are, however, poised to extend into 2022 and possibly beyond. This holiday shopping season, ordering early may not be enough.