Choosing the wrong manufacturer is one of the most expensive mistakes a brand can make. Quality issues, delays, ghosting, hidden costs — nearly every sourcing horror story traces back to one thing: poor vetting.

This checklist gives you a clear, step-by-step process to evaluate any sourcing agent or overseas factory before you send a PO. It’s the same framework Sourcify’s team uses when adding factories to our pre-vetted global network.

1. Verify Business Legitimacy and Credentials

Start with the basics: is this partner who they say they are?

Documents You Should Always Request

- Business license and registration certificates

- Export licenses and trade permits

- ISO certifications (ISO 9001 is standard for quality management)

- Industry certifications (FDA, CE, RoHS, etc.)

- Factory audit reports from reputable third-party inspection firms

Red Flags

- Hesitation or refusal to provide official documentation

- Different company names across platforms

- “New” companies claiming decades of experience

- No physical address, or only a virtual office

Pro Tip: Sourcify eliminates this step entirely by providing only pre-vetted factories, so you skip months of due diligence.

2. Assess Manufacturing Capabilities and Capacity

It’s not enough for a factory to say they can produce your product — you need proof.

Key Questions

- What is your monthly capacity?

- What is your MOQ?

- What similar products have you manufactured?

- What materials or technologies do you specialize in?

- Can you support both sampling and mass production?

Request Tangible Evidence

- Previous product samples

- Photos or videos of production lines

- List of current clients (with permission)

- Production timelines for similar SKUs

Warning Signs

- Vague answers

- Claims of mastering too many unrelated product categories

- No references or samples

- Unrealistic production capacity

3. Evaluate Quality Control Processes

QC failures are the fastest way to drain margin and destroy trust with customers.

What Good QC Looks Like

- Dedicated in-house QC staff

- Testing equipment and lab facilities

- Clear defect rate data

- Documented processes for handling defects

- Willingness to allow third-party inspection

Best Practice: Never load a container without third-party QC. Sourcify requires independent inspections on all shipments before they leave the factory.

4. Check References and Track Record

Proof from real brands matters more than anything a factory says about itself.

Reference Check Process

- Ask for 3–5 recent client contacts

- Search for independent reviews

- Check LinkedIn, social channels, and industry forums

- Look for case studies or published success stories

Questions to Ask

- How long have you worked with this manufacturer?

- Were there quality issues? How were they resolved?

- Were deliveries on time?

- Would you work with them again?

5. Test Communication and Responsiveness

Poor communication is the root cause of many preventable sourcing disasters.

Evaluate Early

- Response time (should be 24–48 hours)

- Professional, clear communication

- Willingness to do video calls

- Understanding of technical details

- Proactive updates during development

Modern Fix: Platforms like Sourcify offer real-time messaging, reducing miscommunication and eliminating scattered WhatsApp threads.

6. Understand Pricing Structure and Payment Terms

Transparency matters more than the lowest quote.

Financial Due Diligence

- Request itemized quotes

- Understand payment terms (30/70 is standard)

- Clarify what fees include (tooling? samples? shipping?)

- Compare multiple quotes

- Investigate prices that seem too low

Payment Safety

- Use secure methods: LC, escrow, Trade Assurance

- Never pay 100% upfront

- Avoid personal bank accounts

- Choose partners who offer payment protections

7. Conduct Factory Audits or Site Visits

Nothing replaces seeing operations firsthand.

If You Can Visit

- Tour production lines and warehouses

- Meet QC, production, and management teams

- Observe worker conditions

- Inspect machinery and process flow

- Review samples being made for other clients

If You Cannot Visit

- Live video tours

- Third-party audit services (SGS, Intertek, BV)

- Time-stamped production photos

- Review recent audit reports

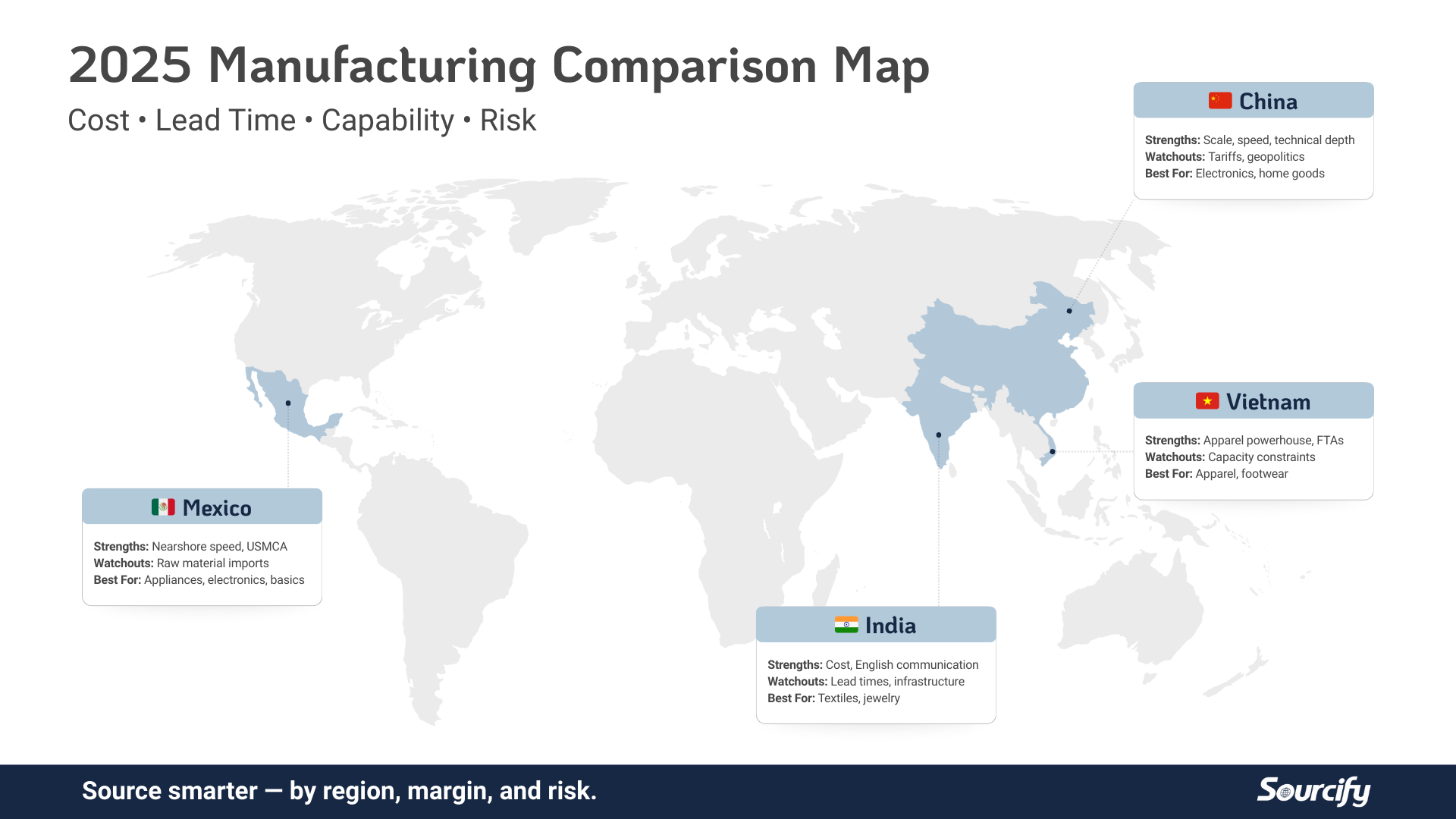

What Sourcify Does: Our teams in China, Vietnam, India, Pakistan, and the U.S. personally visit and verify factories before they join our network.

8. Protect Your Intellectual Property

IP theft risk is real — but manageable with the right structure.

IP Protection Steps

- Require NDAs from all partners

- Register trademarks and patents in the manufacturing country

- Use contracts with explicit IP ownership clauses

- Limit early disclosure of proprietary information

- Split production across factories if needed

Legal Foundation

- Work with lawyers who specialize in international manufacturing

- Understand local IP laws

- Include penalty clauses

- Register with customs to block unauthorized exports

9. Evaluate Supply Chain Stability

A manufacturer is only as stable as their own suppliers.

Questions to Ask

- Who are your raw material suppliers?

- Do you have backups?

- How do you handle shortages or cost increases?

- How did you perform during recent global disruptions?

- Do you hold material inventory?

Good Signs

- Multiple supplier relationships

- Strong working capital

- Transparent communication

- Flexible sourcing options

10. Test With a Small Order First

Before handing over full production, test the relationship.

Smart Pilot Process

- Start with samples

- Place a small initial order

- Inspect everything on arrival

- Document issues and evaluate responsiveness

Evaluate

- Does the product match the approved sample?

- Was the timeline accurate?

- Was communication proactive?

- Were there surprise costs?

- How did they handle problems?

Vetting Is Your First Line of Defense

The truth is simple: most sourcing problems — bad quality, late shipments, disappearing agents, unexpected costs — can be prevented before they happen. Strong vetting protects your brand, your margins, and your sanity.

But doing it correctly takes time, cross-border experience, and on-the-ground factory insight. That’s why so many founders choose Sourcify as their trusted sourcing operations partner.

Let Sourcify Vet Your Next Manufacturer

If you’re evaluating a new factory, expanding into a new region, or planning next year’s production, Sourcify can help you:

- Work only with pre-vetted, high-quality manufacturers

- Gain complete visibility into pricing, communication, and timelines

- Avoid costly mistakes with expert QC oversight

- Build a stable, long-term manufacturing strategy across China, Vietnam, India, Mexico, and more

👉 Book a free sourcing strategy call to review your current suppliers or upcoming production run.

Let’s make sure you’re working with the right factory — before the PO goes out.